Production

MANUFACTURED TO STANDARD AND CUSTOM DIMENSIONS

Cold Forming

Division

Various standard items formed

in room temperature

3-4 MM (MAX. 1/8") | 5-6 MM (MAX. 1/4”) | 6-8 MM (MAX. 5/16")

10-12 MM (MAX. 1/2”) | 13-16 MM (MAX. 5/8”)

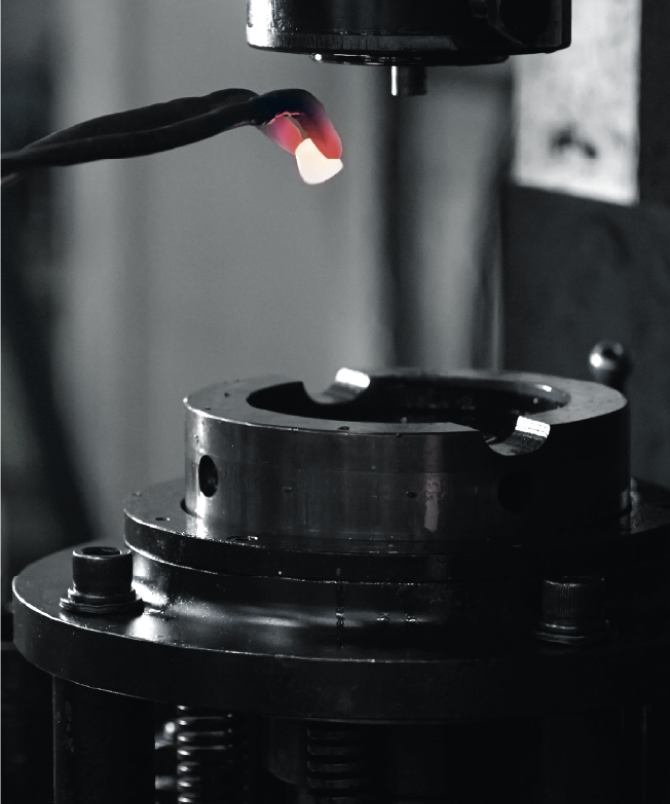

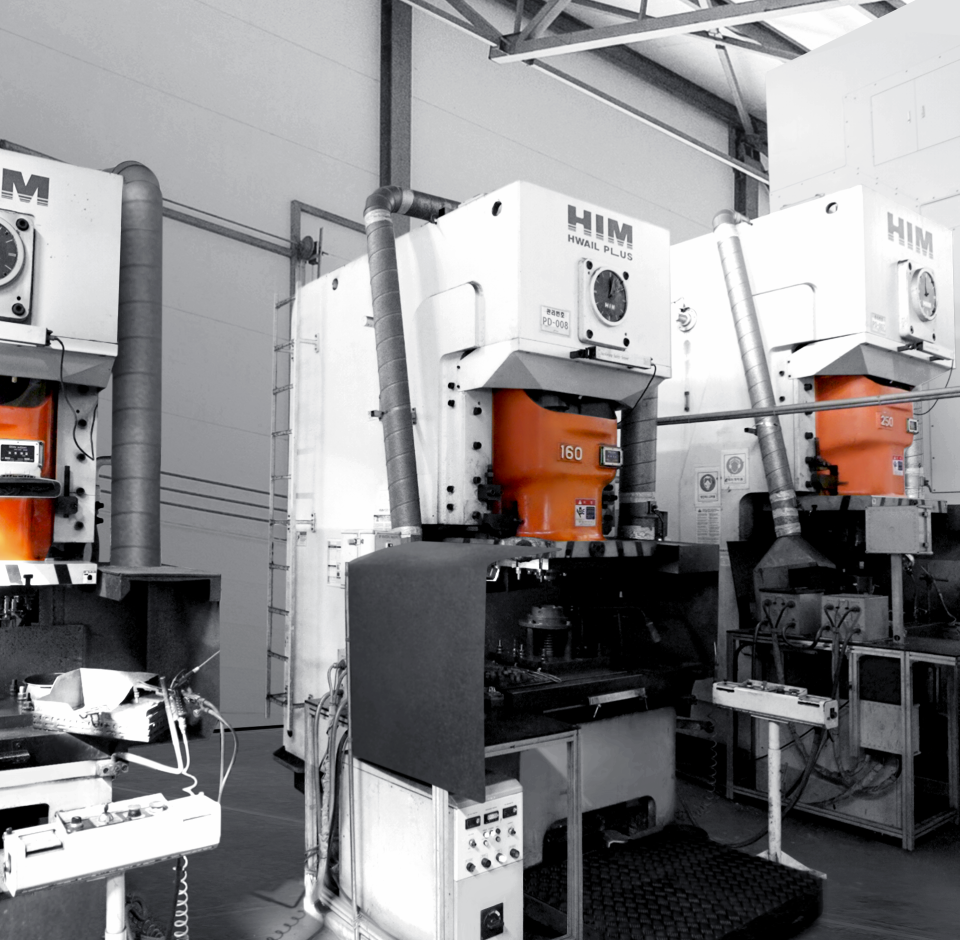

Hot Forging

Division

Hydraulic presses ranging from 110-650 ton

capacities forge standard items in increased temperatures.

Precision Machining

Division

Increased output of custom items through

4 groups of automated CNCs circular-cutting and

edge-preparing simultaneously.

QUALITY

BACKED BY

EXPERIENCE

HASM continuously invests in quality raw material and

monitors

production processes. We answer to customer requirements and

answer to

both standard and custom designs based on

manufacturing experience.

Inventory & Testing

/ Inventory

20M in Raw Material

5M in Finished Products

Vendor Managed Inventory

Maintained by continuous monitoring and

replenishing, allowing quick lead times.

/ Testing

Mechanical and Compositional results

provided by In-house hardness, tensile,

and PMI testing.

PMI Analysis using Bruker S1 Sorter XRF

(X-ray Fluorescence) Spectrometry